Our Press

We provide an in-house laminating and high pressure pressing service at our factory. The maximum board size that our press can handle is 3050mm x 1525mm, although we can achieve longer or wider dimensions by slip pressing.

We offer the option to pre-edge cut to size panels, standardizing panel thickness by passing it through our wide belt contact sander and then pressing each panel with your chosen laminate, this is a good choice if your laminate is through-coloured.

Options for Pressing

We can press the majority of standard substrates – we recommend MDF, chipboard or Birch Ply for a stable core. If your project requires a core that isn’t available from standard board thicknesses we can press a composite of two or more boards together to achieve the thickness that you need.

We can press flame retardant MDF cores with flame retardant laminates where projects require Class B rating. Birch plywood pressed with laminate faces combined with sanded and clear lacquered edges is a common design feature for a contemporary and sustainable look. If you need linoleum desktop pressed onto a core material we can do that too.

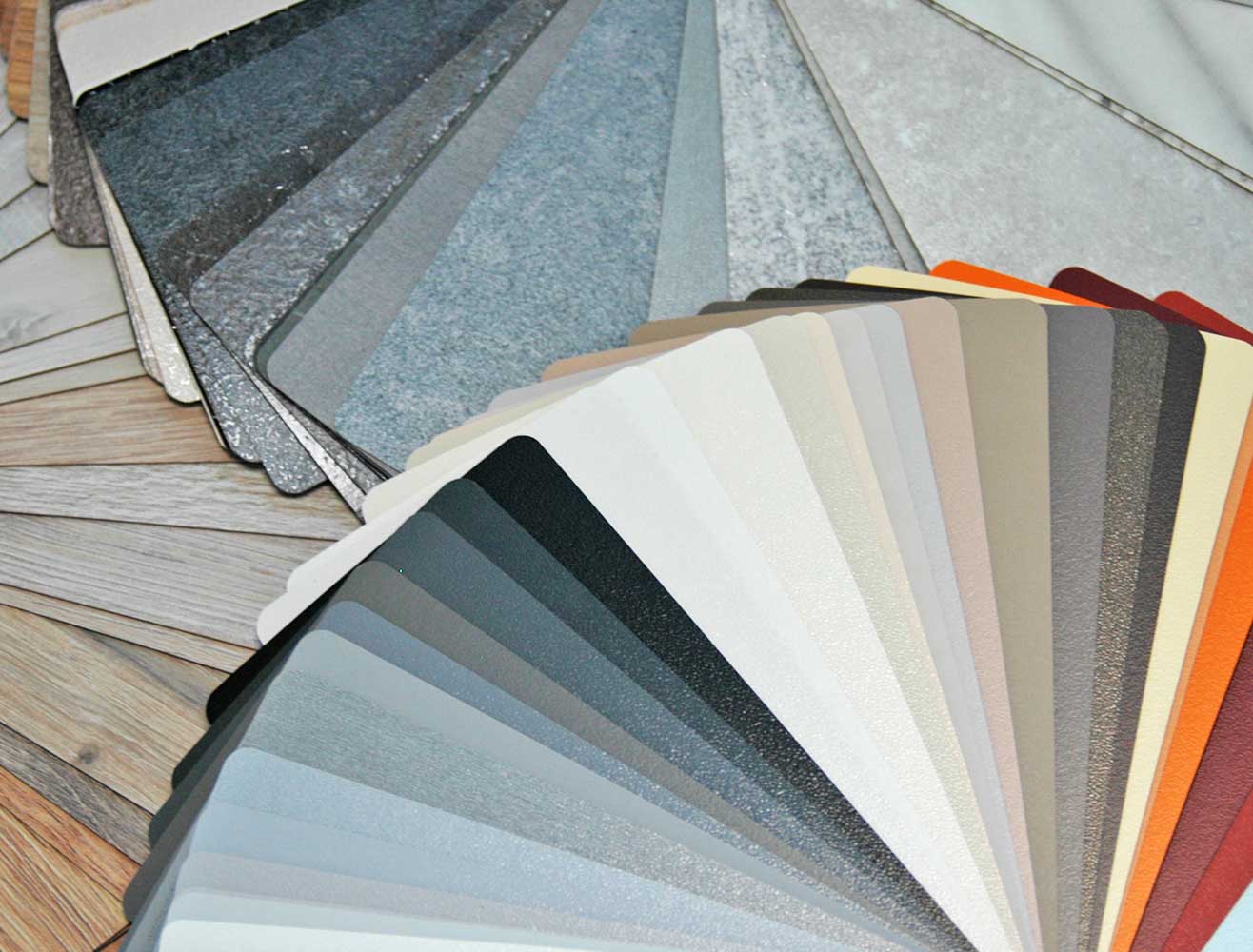

We have access to thousands of laminates from all of the major brands; Egger, Polyrey, Abet, Xylocleaf, Formica, Arpa and more…. and we offer the option to further process your boards through CNC machining and edging with ABS or solid wood lippings or strips of the same laminate to match.

What is HPL?

The decor face of HPL (High Pressure Laminate) is a paper impregenated with melamine resin, this is combined with a backing paper impregnated with phenolic resin sheet and bonded under heat and high pressure. The result is a very durable, stable sheet of laminate. The phenolic backing is visible on the edge of each board as a black line after pressing and before edging.

Please contact us at [email protected] to discuss your project requirements.

Excel enquiry form

Excel enquiry form