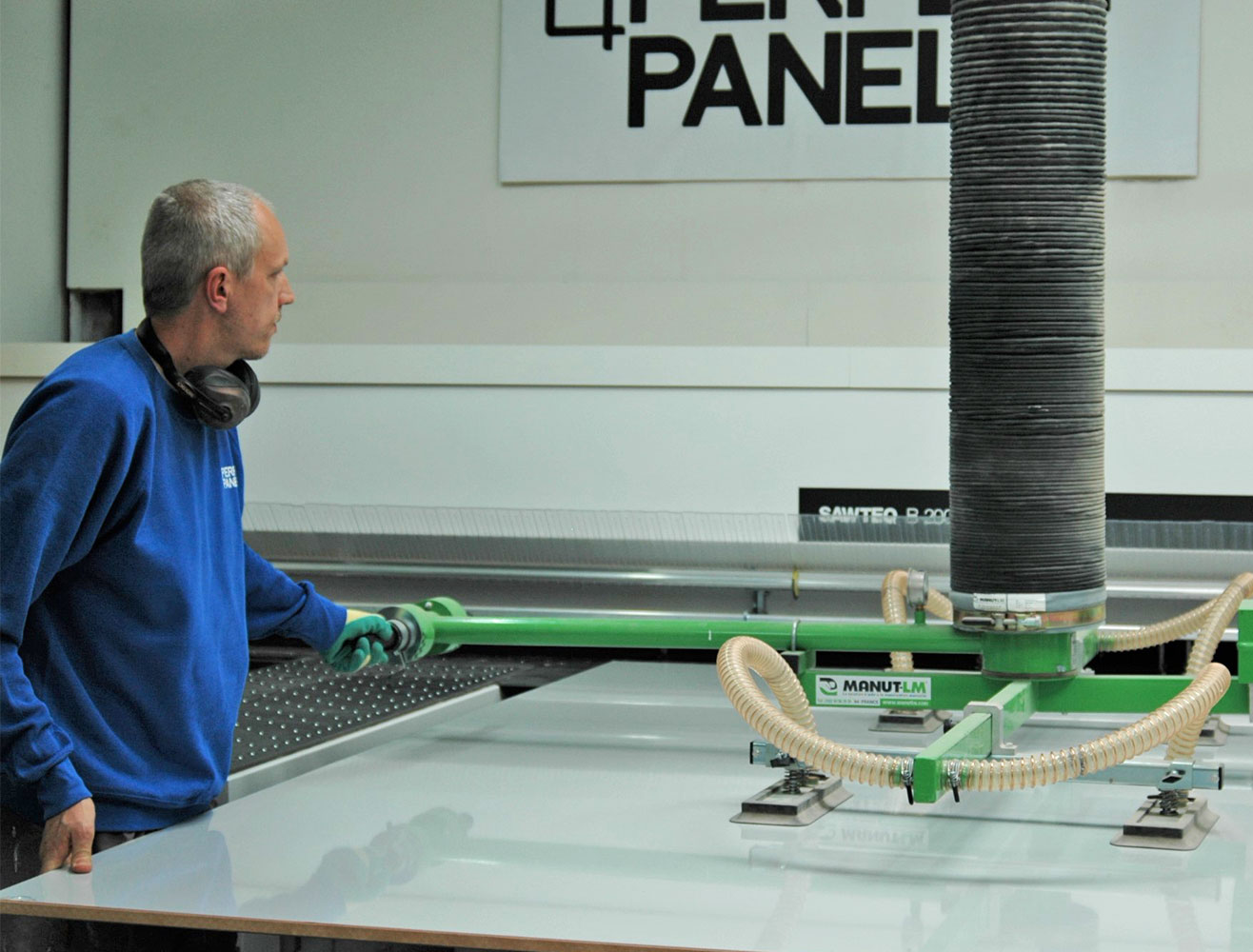

We have recently invested in precision machinery coupled with nesting software to provide maximum yield from each sheet that you select.

Our CNC controlled Beam Saw processes panels horizontally on air flotation tables, cutting at up to 80 metres per minute to ensure maximum speed and efficiency. With side alignment, a large area pressure beam and electromagnetic measuring system our beam saw is able to cut your panels to a tolerance of +/- 0.1mm, however we advise a real-life tolerance of +/- 0.5mm to allow for the normal thermal movement and tensions in timber-based panels when they are processed.

The maximum size sheet that we can process for you is 3200mm long x 3100mm wide, the maximum panel depth is 60mm.

We trim each full board by 15mm all round to provide a perfectly clean cut on your panels, please bear this in mind when inputting large parts on your cutlist.

Each item from your cut list is labelled at the Beam Saw, this label remains with each panel throughout any further processing you have selected (although currently we cannot label items that are sprayed all around), each panel is then easy to identify from your cutting list and quote.

To place your order or get a quote - create your cutting list

Our factory also houses a 5-axis Homag CNC for shaped panels, drilling, routing and line boring - please contact our sales team for further information or a quote.

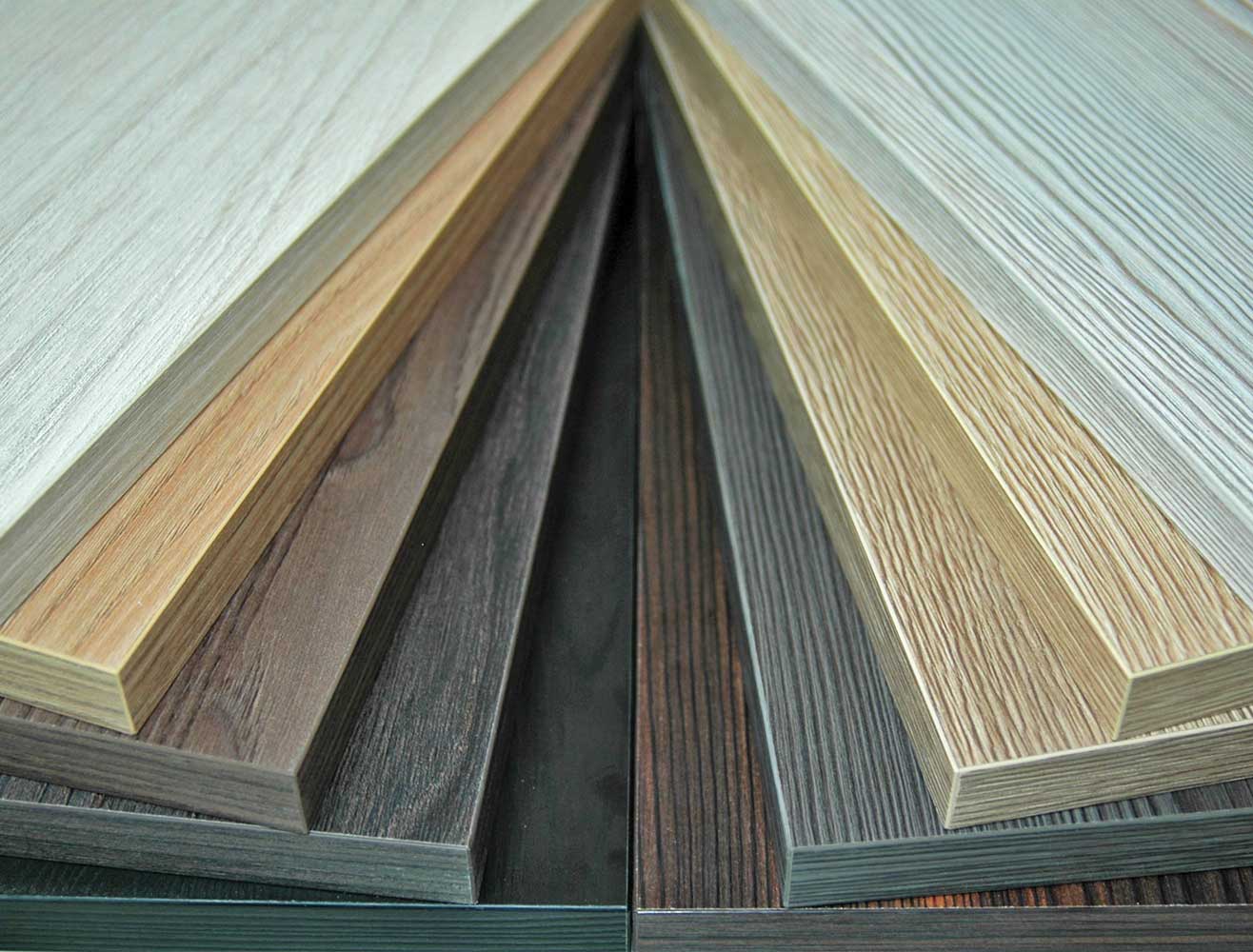

Can’t find the sheet material that you are looking for? Please contact us and we will be happy to help.

Excel enquiry form

Excel enquiry form